Fabrication

SUBTEAMS

WHAT THEY DO

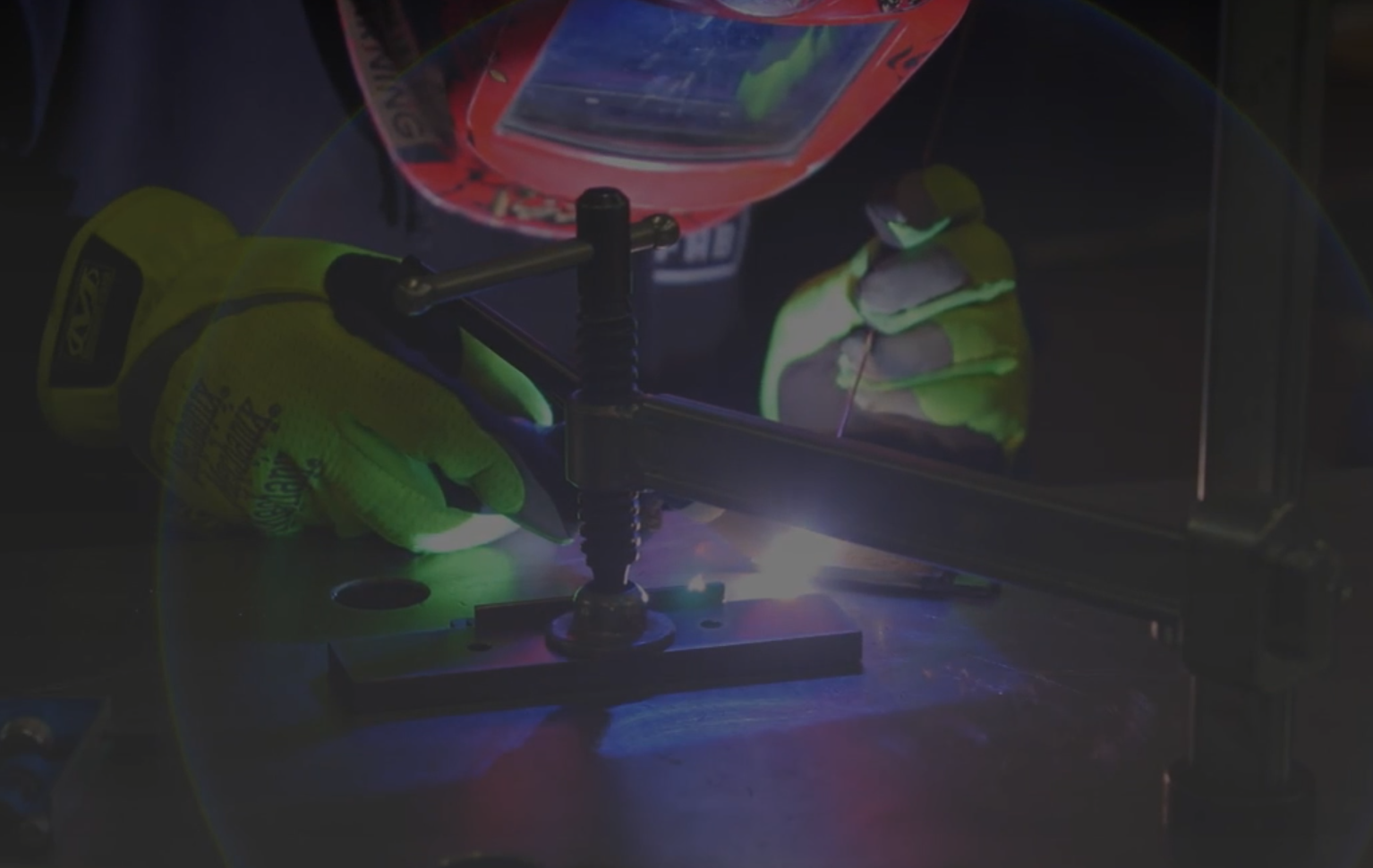

Turning Design into Reality

The Fabrication subteam is responsible for preparing the steel parts of our bridge. Utilizing various power tools ensures the constructibility and ease of member assembly for our welder.

This involves coordinating the procurement of materials, fabricating parts and assemblies to specification, and contacting industry professionals for tasks beyond our in-house capabilities.

RECENT PROJECTS

Learn Manufacturing

This year, the Fabrication subteam is working with other UBC Civil Engineering Design Teams to implement a 5S visual factory in our shared workspace by designing and building organizers and more. By working towards industry standards, the goal is to minimize waste and make life easier for everyone involved.

One of Fabrication’s latest projects was working on creating storage systems for CHBE 104 alongside the Drafting subteam. This exercise gave Drafting an opportunity to learn about the Fabrication package. In pairs, each team designed and built an improvement to the workshop. This includes shelves, cabinet dividers, and sliding drawers.

Recently, members became more acclimated with fabrication by working through their woodworking unit, where they learned how to think, measure, and keep the shop clean properly.

TEAM ENGAGEMENT

“When I joined Fabrication, I looked forward to the opportunity of gaining hands-on experience, as well as participating in something different from my typical academic routine. My expectations have been completely exceeded; not only have we learned how to operate different tools, but we’ve been immersed in the fabrication process as a whole, learning skills applicable both inside and outside of the workshop!”

— Josh Yamada | Fabrication Member 2024